Important

Ores of Iron:

SN

|

Ores

|

Formula

|

1

|

Haematite (Red)

|

Fe2O3

|

2

|

Magnetite

|

Fe3O4

|

3

|

Siderite or Spathic

|

FeCO3

|

4

|

Iron Pyrite (fool’s

Gold)

|

FeS2

|

5

|

Goethite

|

FeO(OH)

|

6

|

Limonite

|

2Fe3O4.3H2O

|

Others Ores

|

||

7

|

Ilmenite (FeO+TiO2)

|

FeTiO3

|

8

|

Chromite (FeO+Cr2O3)

|

FeCr2O4

|

Extraction process of iron: Iron is extracted

from if oxide ores especially form the magnetite, Haematite, and Limonite ores.

The extraction involves the following process.

(1) Enrichment of concentration of

ores:

(A)Dressing or Benefaction of the ore: After mining, Iron ore is first broken into small pieces of 3 – 5 cm in size.

(B)Magnetic and Gravity Separation: Use due to the

presence of metal carbonate

(2) Conversion of ores into oxide

ores:

(A) Calcination: Heating ore in the absence of oxygen below melting

point moisture and CO2 are removed.

(B) Roasting: Heating of

ore in the presence of oxygen below melting point. During

roasting P, S, C, As, Sb etc. are oxidized to the respective oxides and removed.

(i) Fe3O4 is

decomposed to ferrous oxide (FeO) and ferric oxide (Fe2O3).

(ii) Ferrous oxide reacts with silica to

form ferrous silicate at high temperature.

(ii) The conversion of FeO into Fe2O3

will prevent the formation of FeSiO3 Thus mass of

the ore becomes porous causing the increase in the effective surface area.

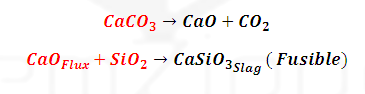

(3) Smelting:

The

calcined ore is mixed with Limestone (Flux) and Coke (a reductant) and smelted in Blast

furnace.

Reaction in Blast furnace: A blast furnace is used for

smelting to produce industrial metals, generally pig iron, but also others such

as lead or copper. The blast

furnace is a huge, steel stack lined with refractory brick, where

iron ore, coke and limestone are dumped into the top, and pre heated air is

blown into the bottom.

(1) Zone

of combustion: (900 -1500 K): This is the higher temperature range found at

lower part of blast furnace

(2) Zone

of reduction: (500 – 800 K): This is lower temperature range found at upper

part of blast furnace.

(3) Zone

of slag formation: (1070-1270 K): Middle part of blast furnace:

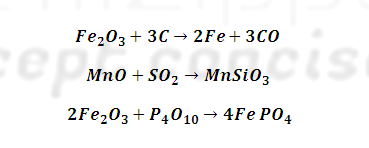

Other impurities

like P4O10 and SiO2 and MnO2 also

reduced

(4) Zone of fusion: (1570 – 2170

K): lower part of furnace.

Molten iron is

heavier than molten slag. The two liquids are periodically tapped off and solidified into

blocks called pigs. And thus Iron obtained from blast furnace is

also called pig

Iron.

Type of Iron:

(1) Pig Iron: Composition:

SN

|

Impurities

|

%

|

1

|

Carbon (C)

|

3- 4.3

|

2

|

Silicon (Si)

|

1-2.0

|

3

|

Manganese (Mn)

|

0.5-2.0

|

4

|

Phosphorous (P)

|

0.05-2.0

|

5

|

Sulphure (S)

|

0.05-1.0

|

(2) White Cast Iron: When re molted pig iron is suddenly cooled,

white cast iron is results. In this form of cast iron carbon is found to be

combined form as cementite (Fe3C).

(3) Grey Cast Iron: However when re molted pig iron is slowly cooled,

Grey cast iron is results. In this form of cast iron carbon is found to be

combined form of Graphite.

(4) Wrought

iron:

This is done by

heating cast iron with haematite (Fe2O3) which oxidises C

to CO, S to SO2 Si to SiO2, P, P4O10

and Mn to MnO . Where CO and SO2 escapes, manganese oxide (MnO) and

Silica (SiO2) combine to form slag.

Similarly

phosphorus pentoxide combines with haematite to form ferric phosphate slag.

Manufacturing

Process:

Casts

iron takes in Puddling

furnace and melted by hot blast of air. The chemical reactions which

occur are:-

On

removing impurities, the melting point rises and it becomes a semi solid mass.

The metal is taken out of the furnace in the form of balls which are then beaten under

hammer to separate out the slag. The product thus formed is thus called wrought iron.

No comments:

Post a Comment