When

roasting forms a liquid product, which makes separation easier, it is called smelting. Metal is extracted by heating calcined or

roasted ore with powdered coke in presence of a flux.

Consider,

for example, the smelting of zinc oxide:

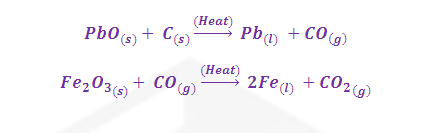

The gaseous carbon monoxide separates from the liquid zinc, allowing the metal to be readily recovered. Other examples are

Slag:

In some

cases, a flux must be added to the mixture during smelting to help separate the

two materials. The flux is a material

that will react with the gangue to form a substance with a low melting

point. For example, oxides of silicon within gangue can be liquefied by

reaction with calcium carbonate according to the reaction:

The waste liquid

solution that forms from the flux and gangue is usually a silicate material

called a slag.

The liquid metal and the liquid slag have different densities and therefore

separate. Holes tapped at different heights into the side of the container

holding the liquid metal and slag allow the more dense liquid to flow out of

the lower tap holes and the less dense liquid to flow out of the higher tap

holes.

Principle of Slag formation:

The

principle of slag formation is essentially the following:

Nonmetal oxide (acidic) +

Metal oxide (basic) to form

a Fusible (easily melted) slag

Removal

of unwanted basic and acidic oxides: For example, FeO is the impurity in

extraction of Cu from copper pyrite.

Matte

also contains a very small amount of iron (II) sulphide.

To

remove unwanted acidic impurities like sand and P4O10,

smelting is done in the presence of limestone.

Properties of a Slag:

(1) Slag

is a fusible mass.

(2) It has

low melting point.

(3) It is

lighter than and immiscible with the molten metal. It is due to these

impurities that the slag floats as a separate layer on the molten metal and can

thus be easily separated from the metal. The layer of the slag on the molten

metal prevents the metal from being oxidised.